Introduction and Comparison of Advantages and Disadvantages of Mobile Crusher Plant, Semi-Mobile Crusher Plant, Semi-fixed and fixed Crushing Plants

The production of open pit mine is inseparable from the crushing equipment, the use of suitable crushing station can effectively reduce the height of rock transport and improve the production efficiency. According to the degree of fixation of the crushing plant and the foundation, the surface crushing plant is divided into: mobile crusher, semi-mobile crusher, semi-fixed and fixed crushing plants. This article analyzes and compares the classification of these 4 types of crushing plants and their advantages and disadvantages, hoping to bring some help to your selection.

01、Mobile Crushing Plant

Generally, it integrates feeding, crushing and conveying, and mobile crushing plant adopts crawler type or tire type (also step type), which can adjust its position at any time in the quarry with the movement of the working surface.

Advantages of Mobile Crushing Plant

Replaces dump truck, reduces procurement cost; reduces transportation cost by 50% to 70%; reduces spare parts cost; reduces labor cost; reduces quarry road maintenance; both safety and environmental protection features. Because it is a trinity of equipment, and the continuous transport equipment connected to it is a belt conveyor, so the crawler type mobile crushing plant is more suitable for large surface mines, suitable for large-scale, continuous mining process.

Disadvantages of Mobile Crushing Plant

The equipment is complicated and expensive, and the one-time investment is too large for the mine to bear economically.

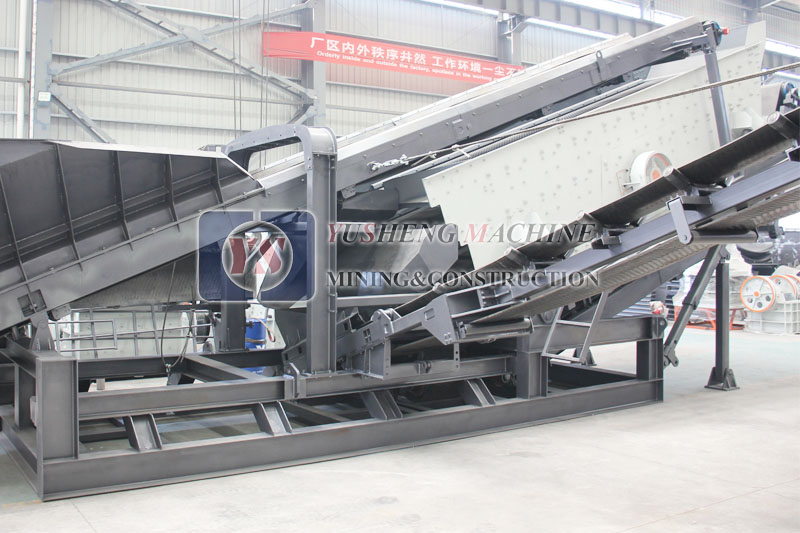

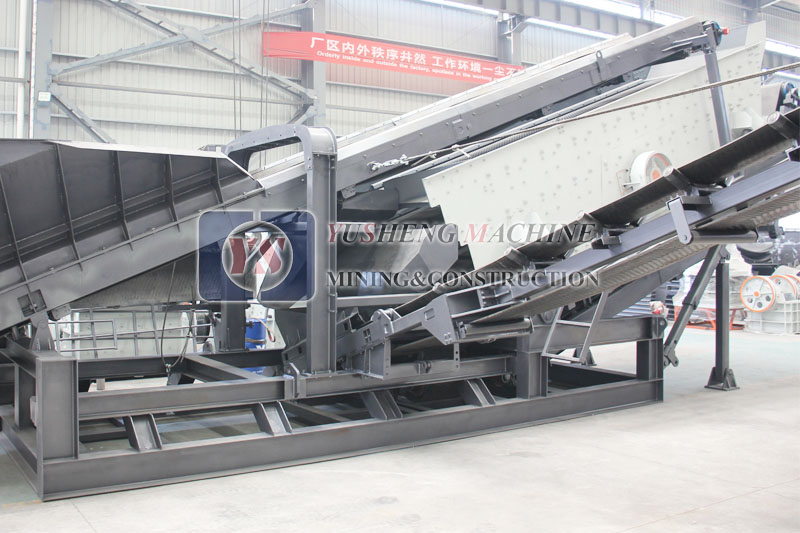

02、Semi-mobile Crushing Plant

The semi-mobile crushing plant, also called modular unit or sled unit, which is placed on a suitable working level in the open pit, and the crushing unit is transported as a whole (or split) by a crawler or other traction (pulling) equipment as the operating platform advances and extends.

A modular unit consists of three major parts: one is crushing, screening or feeding equipment; the other is non-standard design and fabrication parts such as steel structure support, hopper, buffer bin, etc.; the third is standardized design and fabrication parts such as steel grating platform, inclined body, handrail railing, etc.

The most typical feature of semi-mobile crushing plant is that it is connected to the ground without concrete foundation, and its service life varies from several months to several years, and its one migration time usually does not exceed 48h.

The difference between semi-mobile crushing plant and mobile crushing plant is not only the migration time, but also one of the more important features is the part of equipment arrangement. Semi-mobile crushing plant is usually arranged on the working surface of quarry, and the ore rock transportation distance is less than 3km, and when the quarry steps extend beyond the reasonable transportation distance and climbing height of the car, then the next migration is carried out.

Advantages.

Both have the advantage of being able to move, and overcome the disadvantages of semi-fixed building station and long moving setting time:.

a. Overall design and supply: The host equipment, steel structure non-standard parts and standard parts such as aisle escalators are designed and supplied as a whole set, which saves time and effort for the owner and makes construction and installation fast and efficient.

b. Short construction period: It can be manufactured and pre-assembled in the factory, and then split and shipped to the project site for quick assembly after troubleshooting the installation, and each component is connected by bolts, almost no on-site welding is required, which is conducive to fast construction and production.

c. More reasonable investment: less civil construction work, no concrete construction above ground, low labor intensity, low proportion of investment in equipment and steel structure to total investment, and steel structure still has high residual value after a certain number of years.

d. With the ability of mobile transfer, it can be split and transferred to another location for installation and use again, but the frequency of transfer should not be too high.

03、Semi-fixed crushing plant

Semi-fixed crushing plant is a transitional way to develop semi-mobile crushing plant to fixed crushing plant. From the connection with the ground, the crusher frame has a solid connection with the ground (anchor pile connection can be used for bedrock parts, and reinforced concrete foundation can be used for loose square area), and from the location of deployment, it should be fixed on the fixed gang of the quarry generally, so as to reduce the frequency of shifting and improve the use cycle as much as possible, especially for rock This is especially important for rock crushing and transportation.

When the semi-fixed crushing plant is moved, only the equipment body with bolted foundation can be disassembled and moved for reuse, while the foundation buried below the surface is discarded.

Advantages.

The semi-fixed crushing plant can be large in size during selection because of the solid foundation, and is suitable for mines with larger processing capacity and long service intervals.

Disadvantages.

To build a fixed foundation, the construction period is long, the amount of work to move the set-up is large, the operation time to move the set-up is long, and the civil construction cost is high.

04、Fixed Crushing Plant

Fixed crushing station is usually arranged outside the boundary of the quarry, or set up inside the quarry and the joint arrangement of the shaft, not affected by the extension of the quarry steps, and the ground has a permanent fixed foundation connection, after the completion of permanent use, do not move. Its feeding method has diversity, can be directly unloaded into the car, can also be set up buffer bin by the discharge device feeding, fixed crushing plant is generally in the crushing plant of the processing plant, with the mine life.

Disadvantages.

Its biggest disadvantage is that the ore transportation distance is long, the transportation cost is large, and it is not suitable for reasonable adjustment.

05、Comprehensive Analysis

(1)Mobile crushing plant is self-driven in terms of its own walking ability, and the typical walking methods are tire(wheeled) type, crawler type and step type; from the deployment position, it is generally located at the operating surface of the quarry and has to move flexibly with the advancement of the mining face.

(2) Semi-mobile crushing plant, which does not have its own walking function and needs to be transported as a whole or in parts with the help of special shifting tools, and does not need to be connected to the ground. The sled type crushing plant is also included in this category. From the deployment position, to be arranged in the work gang or non-work gang, with the steps down, the car distance increases, and migrate to the appropriate location below.

(3) Semi-fixed crushing plant has obvious connection with the ground, the crusher needs to be installed on an effective concrete foundation or steel structure, and in terms of the arrangement part, to be placed on the fixed gang, of course, there are some examples, because of the terrain and geological conditions, the need to build a more solid foundation on the working gang to place the crusher, also classified in the semi-fixed crushing plant.

(4) Fixed crushing station is the least controversial in terms of classification, with a solid foundation, used for a long time outside the quarry, with a more solid transport distance, and should not be adjusted.